Hand-Crafting a Custom Stained Glass Window

If you’ve long admired the intricate detail, superb craftsmanship and luminous beauty of stained glass, you might want to find out more about this fascinating art form.

All stained glass windows and doors at Fort Worth Stained Glass are custom designed, so you will first work with one of our designers either in your home, or via phone and computer, to create your design. But this is only the beginning of a meticulous process which leaves little room for error. Once you have approved the final design, the actual hand-building of the stained glass piece commences.

The Stained Glass Creation Process

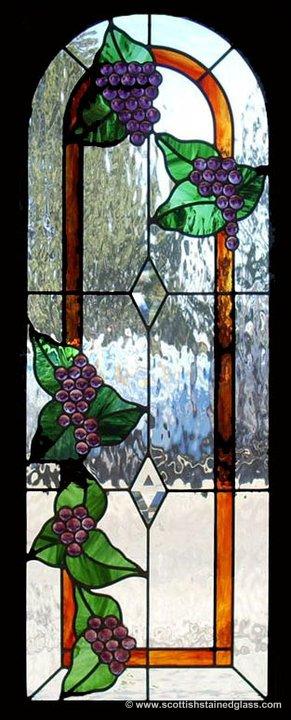

The glass for the piece is ordered and the blueprint for the panel, known as a “cartoon,” is sent to one of our talented artisans, known as builders. We use both domestic and imported glass, some hand blown, some textured.

By the way, each custom stained glass project is worked on by only one builder, from start to finish. There is no assembly line!

By the way, each custom stained glass project is worked on by only one builder, from start to finish. There is no assembly line!

Here’s what happens next:

- The builder will begin cutting the glass, by hand, into the exact shapes and sizes shown on the cartoon. Glass cutting is accomplished with a hand tool that scores the glass, allowing the builder to simply snap it along the scored lines, winding up with the correct size pieces.

- The strips of lead that hold the pieces of glass together are cut to size as well. (Hence the term, “leaded glass.”) Alternatively, the builder might use brass or copper. (In fact, copper was the preferred choice by Tiffany, maker of those famous lamps you might be familiar with.) These strips of metal are called “caming” and come in different widths, from 1/8” to 1” wide. The choice of caming makes a huge difference to the look of the finished piece, so this is a design feature which needs to be decided upon beforehand.

- The caming has a channel running down each side, into which the pieces of cut glass are inserted. At the corners, a tiny drop of solder is added to cover and seal the joint and stabilize the piece. When the entire piece is assembled, it is turned over (very carefully!) and solder is applied to all the joins on the other side as well, for added stability.

- Next up – all of the lead strips are sealed to the glass with a product called Inland Cement, a mud-like or putty-like product. This product dries in a few days, curing to maximum sealing capacity in a week. But like the grout you might use on a mosaic, it leaves a residue which needs to then be removed.

- Lastly, the stained glass panel is polished with an electric brush, removing any excess mud, and giving the finished piece the beauty and luster you’ve come to expect from quality stained glass.

As you can see, stained glass is an exacting art form, requiring patience, precision and a high degree of organization to make sure the correct color and texture of glass wind up exactly where they should be, as shown in the cartoon.

All of our stained glass work is custom designed and hand-crafted. I think you can see why we at Fort Worth Stained Glass are so proud of our work and our artists. To see some more samples of our work, please browse through our online gallery.